Our team aims to design and implement low-cost data monitoring and develop innovative techniques to brew novel, high-quality beers through various projects.

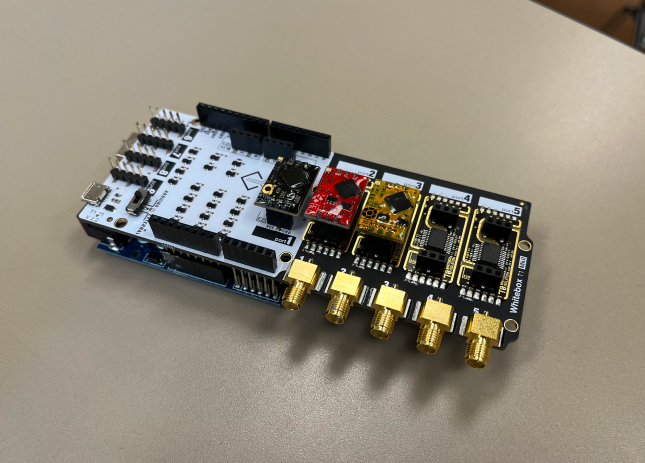

The instrumentation team is responsible for creating equipment to sense brew data and automate tasks associated with the brewing process, and culminate it into a central web app. Common parameters to control are temperature, pH, dissolved oxygen, and specific gravity.

The brewing team is responsible for innovative recipe design, equipment maintenance and operational excellence. This sub-team utilizes biochemical theories learned in class with brewing science and industry knowledge to sustainably operate a bench scale brewery, run quality control assays (QC) and optimize utilization of waste streams.

The lab team is responsible for testing the final product for quality control as a simulation of real-world quality control processes. The team creates data clusters to develop models for brewing process data and uses laboratory equipment to test properties beyond the instrumentation team’s abilities.